Due to the nature of its technology, nuclear power is subject to strict regulations and intense pressures over operational safety. Additionally, nuclear new build projects are increasingly facing a unique set of challenges including high commercial risk, deployment uncertainty, and cost and schedule overruns. In the West, technological innovation activities over the past three decades have struggled to overcome these challenges.

The nuclear industry is not alone; similar features characterised the space sector, but since 2008 it has been showing an increase in commercial activities. A comparative study with the U.S. space industry was conducted to analyse the innovation process that has evolved within the industry, since its long period of stagnation and constraint following the Challenger Accident in 1986. The study confirmed the need to drive institutional and organisational change within highly regulated industries to support technological innovation efforts within private-led initiatives.

This research focuses on the role of ancillary technologies and suggests that they are under-utilised in nuclear new build projects. An institutional change strategy is proposed to facilitate their adoption for faster, better, cheaper nuclear new build in the UK. Parallel studies in the U.S. nuclear industry explored the case studies featured in this paper to drive innovation efforts in advanced nuclear technologies.

Change Management; Organisational Innovation; Technological Innovation; Comparative Study; Institutional Inertia; Civil Nuclear R&D; Highly Regulated Industries

Acronyms

AGR - Advanced Gas-cooled Reactors; BEI- The Department for Business, Energy and Industrial Strategy (2016 - ); CAT- COTSP Advisory Team; COTSP- Commercial Orbital Transportation Services Program; DECC- The Department of Energy and Climate Change (2008 - 2016); DTI- The Department of Trade and Industry (1970 - 2007), EdF Électricité de France, a French electric utility company; EFWG - The UK’s Expert Finance Working Group on Small Reactors; EPC- Engineering, Procurement And Construction; EPRI- Electric Power Research Institute; EPMA - European Powder Metallurgy Association; ETI- The Energy Technologies Institute; FBC- NASA's Faster, Better, Cheaper initiative; HPC- Hinkley Point C; IAEA- International Atomic Energy Agency; IEA-International Energy Agency; IP- Intellectual Property; ISS- International Space Station; LCOE- Levelised Costs of Electricity; MP- Member of Parliament; NAO- UK's National Audit Office; NASA - National Aeronautics and Space Administration; NEAOECD- Nuclear Energy Agency; NEI- Nuclear Energy Institute; NIRAB- Nuclear Innovation And Research Advisory Board; NPP- Nuclear Power Plant; NRC- Nuclear Regulatory Commission; U.S., OECD- Organisation For Economic Co-Operation And Development; OI- Organisational Innovation; ONR- Office for Nuclear Regulation, UK, R&D- Research and Development; SpaceX- Space Exploration Technologies Corporation; SMR- Small Modular Reactor; TDM- Technology Demonstrator Missions; TRL- Technology Readiness Level; ULA- United Launch Alliance; a joint venture between Lockheed Martin and Boeing; WNA- World Nuclear Association; WNN- World Nuclear News

Deploying nuclear power plants (NPPs) is seen as an inherently expensive endeavour due to institutional and technological inertia, spiralling costs and reduced learning within the industry [1,2,3,4,5,6]. As a result, despite the potential role of nuclear power in tackling climate change, no new NPPs have been commissioned in the West since the year 2000. This research suggests that technological innovation in ancillary technologies could lower the costs and shorten the timeframes associated with deploying new NPPs. However, achieving such technological innovation is difficult because of a number of distinctive challenges in the British nuclear industry. Advanced manufacturing technologies, such as electron beam welding which has been used worldwide since the 1960s [7,8,7] and wireless technologies which have been adopted in multiple industries and applications such as in transportation, the military and in fossil-fuelled power plants [9,10,11], are not fully implemented especially in safety-related applications in the delivery of nuclear new build projects (referred to hereafter as new build) [7,9, 11, 12, 13].

This paper presents a study exploring the reasons behind the under-utilisation of effective ancillary technologies. The research makes a novel contribution to the literature by focusing on the interrelationship of organisational innovation with take-up of new technologies, and on the lessons available for nuclear-new-build projects from institutional and organisational change in the U.S. space sector as a comparator.

The successful harnessing of nuclear power for electricity generation presented strategic opportunities to the countries engaged in developing nuclear technology. In addition to national security purposes, exporting civil nuclear technology meant the spread of national influence as well as commercial gains, and these opportunities caused the national strategic importance of nuclear power to rise [14]. Consequently, in the race to commercialize and export nuclear technology, the fifties and sixties witnessed the most intense activities in technological innovation in the West [14]. Amongst other influences, this determination from a number of states to be the first to export their nuclear technology resulted in the swift evolution of reactor technology from the first generation of prototype reactors (Gen I) commissioned in 1956, to the second generation (Gen II) of commercial reactors commissioned in the late 1960s [15], as shown in Figure 1.

Figure 1: Nuclear Power Generation to Generation

However, since the 1980s the nuclear sector faced a number of challenges that made it less cost-competitive with other power sources:

- The effects of the Chernobyl disaster on policy-makers and publics [3,16,17].

- Worsening price competitiveness compared to oil and gas whose prices fell in real terms [18].

- Policy makers’ perception of energy sufficiency in the West [17].

From a brief historical analysis of the problems facing the British nuclear sector, two key questions arise. First, what constrains technological and organisational innovation in the sector, and what would support them? Second, where can lessons be drawn from the space sector for nuclear given the highly distinctive characteristics of the latter sector? This study reviews the challenges facing technological innovation and forms the basis for a framework for understanding the interdependency of technological innovation in the nuclear sector with organisational innovation, drawing on analysis of the U.S. space sector and on fieldwork within the UK civil nuclear sector.

The reasons for selecting the space sector as a comparative case study are: the parallels in regulatory pressures; low tolerance for failure; high costs; national strategic importance and high political sensitivity. The space sector was also selected because as well as sharing these features with civil nuclear, it has shown signs of renaissance in technological innovation in recent years [19, 20, 21 ,22, 23], More importantly this renaissance did not feature any radical technologies. The fundamental message from this comparative study is the critical role of commitment from national policy makers and an effective collaborative framework between government and industry, to enable the successful implementation and coexistence of organisational and technological innovation, as described in Section 6.

The U.S. space industry, similar to the nuclear industry, owes its early development to national strategic pressures and still assumes a status of national strategic importance due to the nature of its technology and its utilisation in transporting sensitive military cargo to space. Following the historic landing on the Moon in 1969 and the Challenger accident in 1986, national space programmes faced reduced budgets, technological inertia, increased oversight and rising costs. These factors, among others, have created an operating environment similar to that of the nuclear sector. Recent reports issued by the U.S. think-tank, the Breakthrough Institute, have reached a similar conclusion: that the space industry can offer lessons in innovation management to the nuclear industry [24, 25]. The findings of this think-tank have been utilised by the U.S. nuclear industry to drive a clear strategy from the U.S. Senate and the Department of Energy to support R&D in advanced nuclear technologies.

This paper is structured as follows: Section 2 introduces the innovation frameworks to be discussed in the context of this research. Section 3 discusses the methodology for this research. Section 4 presents a brief historic review of the British nuclear sector. Section 5 depicts the current state of the British nuclear industry, and presents the key challenges facing technological and organisational innovation in nuclear-new-build in the UK. Section 6 presents case studies from the U.S. space industry and identifies relevant lessons for the nuclear sector concerning innovation and change management.

In the course of this research it was found valuable to distinguish between two basic types of innovation, technological and organisational, and to see them as co-evolving and interdependent [26, 27, 27, 28, 29, 30]. Technological innovation is understood here as the introduction of a new or significantly improved product (goods or services) or process (delivery or production methods [27]. Organisational innovation is “the implementation of new organisational methods. These can be changes in business practices, in workplace organisation or in the firm’s external relations” [29].

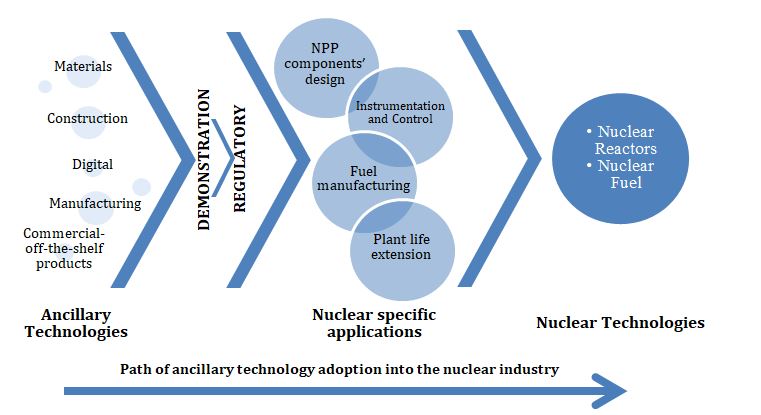

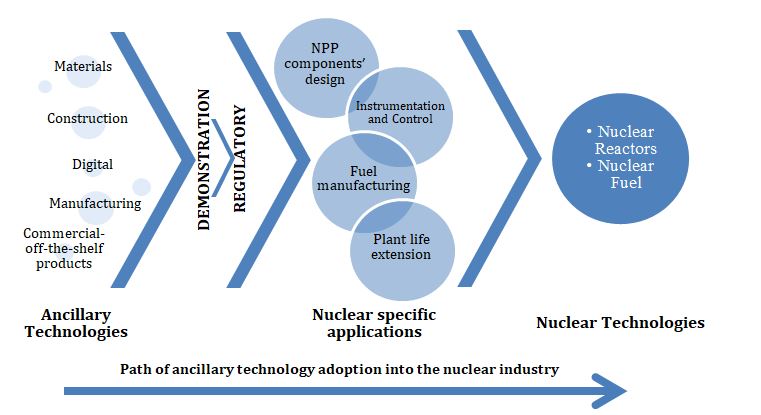

The term ‘technology’ also has a number of connotations. for this research, the term technology refers only to the set of ‘ancillary’ or supporting technologies, such as manufacturing and construction technologies and commercial-off-the-shelf products that can be adopted for nuclear applications. Before these ancillary technologies are adopted in the nuclear context, the reliability and safety of their application must be demonstrated to the regulator. For example, simulation software packages and advanced welding methods modified for the design and build of a reactor vessel are considered to be ‘ancillary’ technologies that were successfully adopted to deliver a nuclear technology. This path of adopting an ancillary technology into the nuclear industry is illustrated in Figure 2.

Figure 2. The Adoption of Ancillary Technologies into the Nuclear Sector

The reason behind the focus on ancillary technologies is their assumed impact on the costs of deploying NPPs. Estimates of the levelised costs of electricity (LCOE, the cost per megawatt hour over the life of the power station), show that 60% of the LCOE is the cost of capital for new NPPs [31]. A breakdown of capital costs shows that engineering, procurement and construction (EPC) form 80% of the capital outlay [31]. Therefore, the adoption of ancillary technologies proven elsewhere, such as manufacturing and construction technologies, would likely reduce the cost and delivery timeframes of nuclear-new-build. However, such technologies are not only limited to reducing the EPC costs of nuclear-new-build; for example, operational costs may also be targeted.

In addition, there is growing interest in Small Modular Reactor (SMR) technologies leading to multiple competitions launched in the U.S., Canada and here in the UK [32, 33, 34, 35, 36, 37]. The latest report from the International Atomic Energy Agency (IAEA), Advances in Small Modular Reactor Technology Developments (2018), reveals that 46% of the proposed reactor designs are based on the dominant light water reactor technology. Developers of these SMRs propose that the adoption of ancillary technologies alongside enhancements to dominant designs could deliver SMR power plants at cheaper costs and shorter timescales than traditional, large NPPs. The comparative study provides evidence that supports this proposal and highlights the role of organisational innovation in facilitating such technological innovation, which is restrained in industries that display institutional and technological inertia.

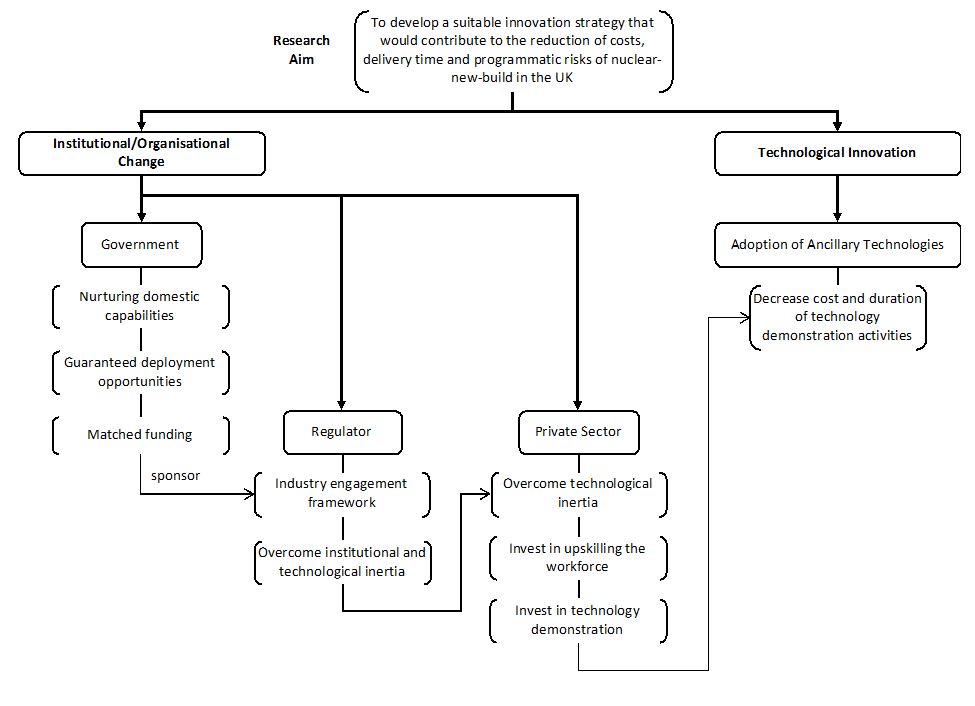

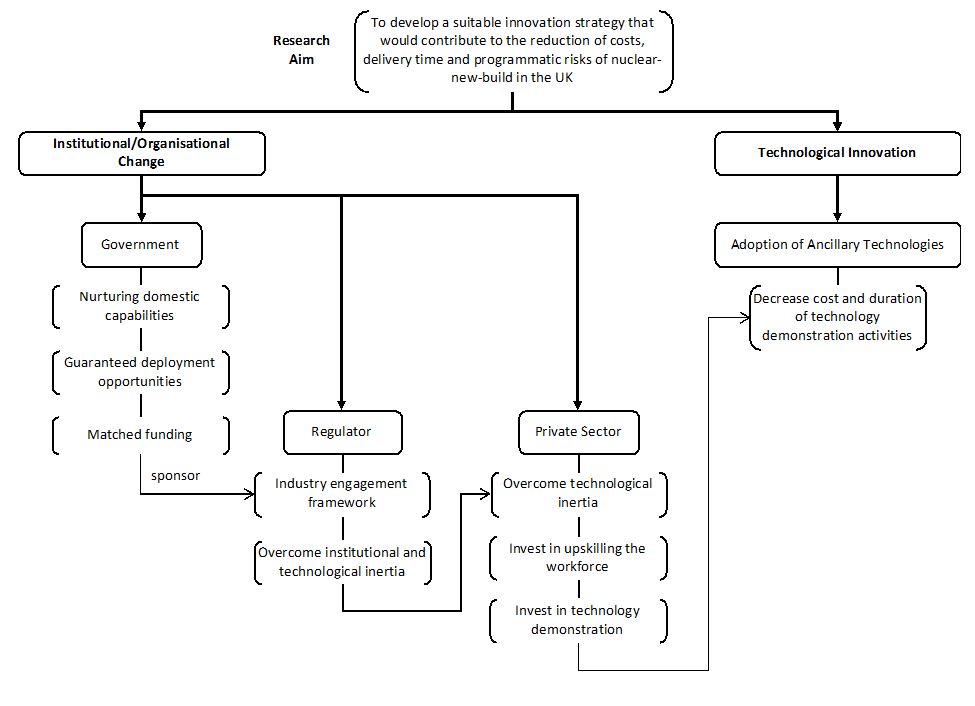

Due to several factors (discussed in the following section), nuclear-new-build in the UK has historically been overbudget, behind schedule and presents high commercial risk to the private sector [3, 38, 39, 40, 41]. As shown in Figure 3 this research proposes two congruent paths to help tackle these highlighted issues through:

- institutional and organisational change, and

- technological innovation. (Figure 3)

Figure 3. Research Aim and Questions

To facilitate institutional/organisational change this research identifies the actors that influence the innovation process within the UK nuclear industry, to then explore the role each actor plays and their impact on technological innovation (Section 5). Through the comparative study, the research suggests how prominent actors could facilitate the adoption of effective ancillary technologies in the delivery of nuclear-new-build in the UK.

The case study approach was utilised in this study due to the requirement for “an experimental inquiry” that investigates contemporary events in depth and in their real-life context [42], and the fact that the researcher cannot conduct a controlled study to isolate variables such as national policy and regulatory acceptance within a context as complex as that of the UK nuclear and U.S. space industries [42, 43, 44, 45, 46, 47].

Academic and grey literature was consulted and interviews with key personnel were conducted to construct a narrative concerning the UK nuclear industry [44, 48] with a focus on innovation management and practices. Historic narrative analysis organised the retrieved historic data to identify actors, events and other factors that have altered the UK nuclear and U.S. space industries. This approach also identified factors that are most likely to influence change within the UK nuclear industry going forward.

The interviews were conducted with professionals in the nuclear industry with an average of twenty years of expertise across a range of skills and knowledge. An observational approach informed the choice of interviewees to better understand the prevailing culture [45]. A drawback of this approach is the possibility of inherent bias in replies from interviewees. The research design corrected for this through corroboration against evidence from the comparative study and wider literature.

The comparative analysis was then utilised as a logical method to describe and understand similarities and differences between industries at the macro-social level [49]. This method of analysis places emphasis on the context when seeking industries prone to similar challenges as a result of parallel, chronological causes. The comparative analysis therefore led this study towards the U.S. space sector, as it identified a number of commonalities between the highly regulated UK civil nuclear and U.S. space sectors.

It is recognised that with the comparative analysis certainty is not possible since it suggests plausible scenarios or influential factors which need to be tested [50, 51] and although within such an “approach the quality of control of the relationship between variables is low, it is often the only scientific method available for the study of macro-dimensional, inter-dimensional and institutional processes” ([46], italics added for emphasis].Conducting a comparative analysis therefore permitted the research to deal with the complexity of the nuclear industry’s context and ensuing research problem [52].

The proposed methodology provided the research with a holistic method to identify and analyse variable configurations of conditions influencing technological innovation in the UK nuclear industry [49]. It also allows the research to understand and explain how the actions and events in one industry could be replicated to generate similar phenomena in the other industry [52]. Therefore, utilising a comparative case provides an additional source of insights to increase the robustness of proposed interventions to facilitate technological innovation through institutional/organisational change in the UK nuclear industry.

Historic Review of Nuclear Power in Britain

In the UK, the 1960s featured an increased rate of NPP deployment, and new NPPs were being continuously commissioned in the 1970s and 1980s. Until the early 1980s nuclear power was seen as a feasible and attractive endeavour due to the oil shocks of 1973 and 1979 and the added requirement of energy security [18]. However, in the 1980s, amongst other influences, falling oil prices led the UK Government to question the plans put forward to commission ten more NPPs. As a result, only the Sizewell B plant was commissioned in 1986 following an extensive public inquiry [18].

In 1990 the generation and distribution of electricity was privatised in the UK, and in the run-up to the restructuring of the UK nuclear sector in 1995, the Government commissioned an economic review of the sector [1, 18]. The review concluded that there was a lack of incentive for government to subsidise and support the industry on the basis of reducing future emissions or other strategic benefits such as, for example, maintaining the domestic industrial base [1]. The private sector was therefore encouraged by Government to lead the investment in and delivery of new NPPs [1].

Since the restructuring of the UK nuclear industry in 1996, UK energy policy underwent a number of reviews. These multiple reviews led to a shift in priorities between the elements of the energy trilemma, i.e. energy security, tackling climate change and energy affordability [18, 53]. In 2007 with energy security and climate change mitigation leading the agenda, a new era for nuclear energy began where government shifted from its earlier position in 1995 to confirm “its (…) view that it is in the public interest to allow energy companies the option of investing in new nuclear power stations “ [54].

From 2007, nuclear energy has continuously featured alongside renewables in the UK’s future energy mix to tackle climate change [55, 56]. The UK Government decided to let market forces “decide which technologies are most effective in supplying the UK’s energy whilst also meeting (…) [the UK’s] carbon reduction goals.” [54] By 2008, however, the UK had no domestic reactor vendor and operator capable of responding swiftly to this change in the political context to deliver an affordable indigenous reactor technology [56], and the skills-base specialized in the delivery of new NPPs was waning [57, 58]. Following this change in policy, Électricité de France (EdF) and a number of foreign companies announced their intention to deploy their nuclear technologies in the UK.

Despite the change in national policy towards supporting nuclear-new-build and rising opportunities for deploying new NPPs in the UK, Toshiba announced its plans to withdraw from the NPP planned at Moorside in 2018, following the Chapter 11 bankruptcy of Westinghouse Electric Company and there being no viable buyer for the project. There has also been growing public concern due to the rising costs of nuclear suggesting that public investments should be channelled towards renewable energy [59, 60]. Furthermore, the Chinese investment in Hinkley Point C (HPC) stirred public concerns over the influx of foreign capital and technology into such a sensitive industry linked to energy and national security [61, 62].

It remains unclear what interventions the UK Government could make to reduce the barriers to entry experienced by private developers. Some observers argue that the criticism facing the HPC project is due to a lack of incentive within UK Government to finance the delivery of new NPPs which would lower the business risk facing private companies [40, 63]. In their assessment of the HPC deal the National Audit Office (NAO) [40] stated that “government contributing to the project’s financing could have reduced financing costs because the government’s cost of borrowing is lower than for private investors”. The report also concluded that the Government’s current “approach to financing nuclear power also reduces the feasibility of it taking a 'fleet approach' where it would simultaneously commission building of several large reactors to the same design. Such an approach can result in significantly lower construction costs through economies of scale” [40]. As a result, the UK Government changed its funding strategy in 2018 to offer a significant investment to the Wylfa Newydd project [64] ; nevertheless Hitachi suspended its project on January 2019, citing that it has “reached the view that the project still posed too great a commercial challenge, particularly given (…) the likely level of return on their investment” [65].

More than twenty years following the restructuring of the nuclear industry, the rationale for the private sector to suspend nuclear new build in the UK still holds: the deployment of nuclear new build in the UK presents too high a commercial risk without significant government support [63, 65, 66]. The increased commercial risk the UK private sector is exposed to has resulted in the R&D focus on nuclear-specific technologies and on decommissioning and waste management applications in the UK civil nuclear landscape, leaving an area of untapped opportunities for nuclear R&D to reduce the costs and timeframes of deploying NPPs.

The author proposes that the nuclear industry in the UK has experienced a lack of context stability and confidence in the market. As illustrated in Figure 4, due to the maturation of the fleet and lack of new build opportunities, the UK nuclear industry has shifted its activities from nuclear-new-build to supporting the operation and decommissioning of NPPs. The UK Civil Nuclear R&D Landscape Survey (2017) report provided by the Nuclear Innovation and Research Advisory Board (NIRAB), has indicated that R&D activities in the UK private sector in 2015/2016, were mostly focused on waste management and decommissioning (46%), reactor technologies (26%), and cross-cutting (ancillary) technologies (10%) [67]. It is inferred from various reports that as a result of the rise of the decommissioning market since 1990, technological innovation and demonstration aimed at the back-end of a NPP’s life cycle, i.e. waste management and decommissioning, has been receiving the most funding from both UK public and private bodies due to clear application opportunities [67, 68, 69, 70]. This in turn can reduce the incentive to seek and implement organisational change within the industry to facilitate technological innovation in nuclear-new-build: due to the high commercial risk associated with nuclear-new-build projects in the UK resulting from historically inconsistent policies and the lack of guaranteed deployment opportunities.( Figure 4)

Figure 4. Summary Timeline of the UK Nuclear Industry, Power Plant (de)Commissioning Activities and Key External Events (Based on DECC, 2015a, IAEA, 2018, NAO, 2017, Pearson and Watson, 2012)

State of the UK Nuclear Industry

The following sections explore the impact of the UK’s historic and recent nuclear landscape on the industry, in addition to potential areas for change management to facilitate the adoption of ancillary technologies in nuclear-new-build.

The UK Nuclear Workforce

The nature of nuclear technology places a high demand on the training requirements for experienced nuclear personnel. A skilled member of the nuclear workforce requires more than 10 years of experience in the nuclear sector, and subject matter experts usually require more than twenty years [71]. Due to the historic uncertainty in NPP deployment opportunities and associated financial returns, respondents have confirmed that private firms are less inclined to invest in the development of nuclear-specific skills [2, 57,59, 72, 73].

Furthermore, one respondent stated that the influx of diverse foreign technologies, highlighted in Section 4, limits the contribution of the UK private sector to those services that possess less intellectual property (IP) value in NPP delivery [74] Figure 5 illustrates that the UK private sector predominantly operates in the mid to lower tiers of the civil NPP supply chain. (Figure 5)

Figure 5. The NPP Supply Chain (adapted from Hoggett, 2014)

Without a domestic endeavour, this limited remit of the UK private sector leaves technology insertion opportunities contingent upon initiatives from foreign NPP developers. Following the recent suspension of nuclear projects in the UK, this limited remit and long-term uncertainty in technology insertion opportunities curtail the learning and knowledge transfer process, which in turn affects the level of skills available within the workforce. Moreover, as a result of the uncertainty surrounding deployment opportunities the full benefits of continuous learning are difficult to achieve in the current UK nuclear context.

The Fleet Approach and its Impact on Learning and Knowledge Transfer

Some respondents agree that standardisation is critical to realise the benefits of learning and, alongside an increased deployment of new NPPs, would facilitate reaching economies of scale [5, 72, 75, 76, 77, 78]. One interviewee revealed that historically the UK AGR and Magnox designs were under constant review and modification; therefore, each reactor and plant is different which, to this day, presents challenges to the operation and maintenance of the fleet [79]. Consequently, standardising an NPP design and production, and deploying it and its associated technologies multiple times will enhance the plant’s technical properties, introduce economic savings, and reduce the programmatic risk of future deployment opportunities due to the experience gained and ensuing transfer of knowledge [80, 81].

To summarise, if the UK Government were to decide to increase its investment in foreign-led developments for ‘one-off’ technologies to lower the commercial risk they face, these projects would create employment within the UK nuclear sector, but these jobs would be limited to low value IP. Since these projects are one-off technologies, the benefits of the ‘fleet approach’ suggested by respondents and the NAO would not be achieved, and the learning acquired from implementing a given technology would have a limited impact when applied to a different one. Such a decision would not encourage the UK’s private sector to invest in demonstrating the safety and reliability of ancillary technologies to enable their adoption in nuclear-new-build projects in the UK. Opportunities for technology insertion are uncertain and limited, and therefore an adequate return on investments cannot be guaranteed, which reduces the incentive for organisational change.

Technological Inertia in the Nuclear Sector

The adoption of ancillary technologies faces a unique set of challenges in the nuclear industry. An example is the delayed certification of Hot Isostatic Pressing: a proven time and cost-effective manufacturing process for components of improved quality [82, , 83, 84]. Despite its development throughout the sixties this process was accepted in 2013 by the American Society of Mechanical Engineers for its adoption on critical, pressure-retaining components, but is yet to be approved by the U.S. Nuclear Regulatory Commission [85], almost 50 years since its inception. On the digital side, field programmable gate arrays, commercialized in the late eighties, were first introduced to limited safety-related applications in NPPs in 2009 [86, 87]; a 20-year lag between development and adoption. Due to such examples and more [7, 8, 9, , 12, 13, 88, 89], this research suggests that the lag in the adoption of ancillary technologies being proven elsewhere to accomplish quality enhancements and cost- and time-savings, is an indication of required improvements in innovation management within the nuclear industry with regard to nuclear-new-build projects, both technological and organisational.

Overall experience from the fieldwork drawn upon here suggests that the technical conservatism that many respondents perceived in the regulator has triggered institutional and technological inertia within the industry. Nuclear experts have stated that demonstrating the safety, reliability and functional validity of a new technology is of the utmost importance before it is adopted in nuclear applications [79, 90]. The challenges facing this demonstration of safety and reliability in the UK nuclear industry have been summarised by one respondent:

“to develop a new technology and a new approach in the nuclear industry with the regulatory constraints and proven technology principles and level of investment required to demonstrate, substantiate the new technology is also a deterrent in many ways because you have to invest a lot of time and lengthy costly programmes without much certainty because that could all be rejected by a regulator at the end point. So there’s a lot more risk in developing technology I would say in the nuclear industry than many other industries; that’s my perspective on it” [59].

Due to similar perceptions observed in the fieldwork, this research identified an inclination within industry to pass preconceived judgements on regulatory approval towards a technology prior to the testing and verification phase. One respondent has highlighted that in the nuclear industry “we just seem very slow to adopt new technologies”[74]. As a result, not only will “the adoption of new ideas [be obstructed] but also their emergence altogether”[91]. This institutional and technological inertia would ultimately hinder the adoption of effective ancillary technologies.

To summarise, the demonstration of a technology’s ‘safety and reliability’ is considered by the nuclear workforce to be an essential, yet resource-intensive, activity in technology development that entails a high level of commercial risk, which comes without guaranteed multiple opportunities for technology insertion (and therefore cost recovery). Additionally, technological inertia delays or hinders the demonstration and adoption of technologies that could drive down the costs and shorten the delivery timeframes of nuclear-new-build initiatives.

Challenges Facing Technological and Organisational Innovation in the UK Nuclear Context

The difficulties in facilitating the learning and knowledge transfer necessary to create a commercially viable ‘product’ and sustainable demand are indicative of a strategic and structural challenge within the current UK nuclear system [92, 93]. Learning plays an instrumental role in effective technological innovation and is proportionate to the rate of technology diffusion [94]. However, a changing context and lack of relevant skills presents challenges to implementing institutional/organisational changes to facilitate technological innovation in nuclear-new-build in the UK.

There is a sense of urgency in driving change within the UK nuclear industry [95]. The guaranteed deployment of new NPPs would aid the recruitment of sufficient numbers into the UK nuclear workforce to facilitate learning and knowledge transfer between new entrants and the skilled workforce approaching retirement. A new build programme also has the potential to provide an up-skilling of the work force through training, technology transfer and indigenous technology development. The high capital costs and build schedule risks inherent to current NPP designs present a high barrier to entry for vendors, utilities and governments alike. Consequently, the UK new build programme has not maintained its schedule and has seen the withdrawal of two key deployment projects. Knowledge transfer, learning and capability within the UK nuclear industry is at risk of decline without the opportunities offered by a new build programme. The loss of indigenous civil NPP vendor capability and the associated R&D programmes due to previous national policies compound the issue. Furthermore, there are inherent high barriers to entry to demonstrate technologies novel to the nuclear industry, which may be seen to have reinforced institutional and technological inertia within the industry.

These challenges to technological innovation in nuclear-new-build in the UK are summarised in Figure 6.

Figure 6. Summary of Research Analysis: Challenges Facing Technological Innovation in Nuclear New Build in the UK

The success of Organisational Innovation (OI) is based on identifying and implementing new business practices, organisational structure, culture, operations, capabilities or external links to improve organisational performance and facilitate positive financial returns [27, 29, 96, 97, 98, 99]. OI therefore targets changes in the “social system of an organisation” [97], to affect the relationships and interactions between members of the organisation, and between them and any other members who work together to achieve a particular task or goal [ 96, 97, 100]. At a macro-social level, such changes in the social system are anticipated to affect the relationships and interactions between the different institutions and actors of an industry.

Management plays a critical role in implementing OI and suitable management systems and managerial skills are required to exploit any acquired knowledge [30, 97, 99]. It is therefore suggested that OI influences the generation of technological innovation since it enhances an organisation’s creativity and flexibility and enhances the delivery of “complex technological innovations” defined as those seeking to deliver both product and process innovations [27].

As discussed above, the private sector is in charge of leading and delivering nuclear-new-build projects in the UK following the sector’s privatisation. Therefore, commercial incentives need to be in place to encourage management to dedicate their resources towards technological innovation, especially considering the technical and commercial risks faced in the nuclear industry. These challenges to implementing organisational change, and the skills gap within the UK nuclear industry, hinder efforts to overcome the institutional and technological inertia exhibited by the industry.

It should be noted that the decision to deploy NPPs is not in the hands of the private sector. It is one made by the Government and led by national policies. In the UK, prior to acquiring a license from the Office of Nuclear Regulation (ONR) to construct and operate a new NPP, the operators of a proposed NPP require the Government’s referral to the ONR for review [101]. Due to the nature of nuclear technology any application to deploy a new NPP has to go through a ‘Justification process’ whereby ‘the Government must first assess it to determine whether the individual or societal benefit outweighs the health detriment it may cause. (…) The process of justification requires that before a practice is introduced, it should be shown to give an overall benefit.’ [102]. Consequently, a change within the landscape of the UK nuclear sector is required to overcome the identified challenges to technological and organisational innovation in nuclear-new-build, and to allow both innovation models to co-evolve as suggested in the innovation literature. The Government, regulator, the private sector and other institutions need to be involved in this change process to reduce barriers to entry and encourage organisational innovation within the nuclear industry. The U.S. space case study illustrates the positive impact of such collaborative efforts to encourage the engagement of the private sector and facilitate effective technological and organisational innovation. Through such efforts the private company Space Exploration Technologies Corp. (SpaceX) emerged as a market leader, with affordable American capabilities to dominate the global commercial launch market.

The comparative study with the U.S. space industry was undertaken to determine how an effective collaborative framework between government and the private sector can support innovation efforts within the industry and decrease the costs and commercial risks of technology demonstration and development. The U.S. space sector case study indicates how institutional and organisational change can be utilised to encourage the adoption of ancillary technologies in highly regulated industries and highlights the impact of a stagnation or decline in technological innovation on industries of national strategic importance.

The iconic landing on the Moon in 1969 was spurred by a national and political desire by the USA to demonstrate technological superiority over the Soviet Union at the height of the Cold War [103, 104]. Despite the great achievements of NASA, there has been no manned deep-space mission since the early 1970s [103]. It is therefore worth focusing on the history of NASA, since the agency includes the diverse aspects of a regulatory system and an innovation and R&D network: it plans, directs, conducts and certifies space-related activities alongside the Federal Aviation Administration [105, 106]. NASA also holds the unique federal authority to enter into agreements with the private sector “outside of federal acquisition requirements” [106].

The scientific, commercial and military benefits facilitated by space technologies and missions are undisputed [107, 108, 109], but prohibitive costs, decreasing federal budgets and heavy regulation have led to a reliance on old technologies and foreign capabilities, especially for rocket launch [19,, 110, 111]. Additionally, the sector also experienced a decreasing number of young entrants to the workforce, due to the then apparent stagnation of the industry in the early 2000’s [112, 113]. This account, of the lack of stability in the U.S. space industry, mirrors the current state of British nuclear energy. However, and as illustrated in Figure 7, the U.S. space sector has launched a number of initiatives to introduce organisational change, reduce barriers to entry and revive domestic capabilities through technological renaissance and private-led initiatives.

Figure 7. Summary timeline of the UK Nuclear and U.S. Space industries and key external events: A Comparison (Abdalla et al., 2019)

The following sections introduce two change initiatives instigated by NASA to tackle its complex context, rising costs and reliance on foreign capabilities. Those initiatives, Faster, Better, Cheaper (FBC) in 1992 and the Commercial Orbital Transportation Services Programme (COTSP) in 2006, ushered a number of managerial and technical reforms within NASA and the U.S. space industry as a whole, and revived the private sector’s role in space transportation. The following sections discuss how organisational innovation in the private sector facilitated the adoption of ancillary technologies, which led to a reduction in the costs of spaceflight. Hence, the experience of the U.S. space industry provides the nuclear sector with a set of case studies that start to inform how change could be implemented effectively within a complex and highly regulated industry to encourage technological and organisational innovation.

The Faster, Better, Cheaper (FBC) Initiative

In 1992, the FBC initiative came as a response to demands from Congress that NASA tackle its budget deficit and reduce its costs [114]. With a renewed focus on research and technological breakthroughs, NASA’s Administrator Daniel Goldin led an aggressive campaign to deliver cheaper and faster smaller spacecrafts at NASA while maintaining a ‘safety, first and foremost imperative’[115, 116]. During his term, the FBC reforms enabled technological innovation to achieve 60% reduction in cost and 40% reduction in the time associated with the development of space- and Earth-science spacecrafts, “while increasing the average number of missions launched per year about four times. During the same time, Space Shuttle costs were reduced by about a third, while all safety indicators and mission capabilities have achieved significant improvements”[116]. Technology Demonstrator Missions (TDMs), which were a staple addition under the initiative, helped develop both space-specific and commercial-off-the-shelf technologies for future missions. These missions fed into existing programmes by advancing space technologies whilst lowering costs and rekindling the enthusiasm within the workforce and young generation in deep space exploration [117]. A summary of the features of the FBC projects is presented in Figure 8.

Figure 8. Faster, Better, Cheaper - Doing more for less (Based on McCurdy, 2003, Spear, 2001)

TDMs managed to reduce the risks, costs and time associated with technological innovation to advance capabilities for more critical, complex missions. More importantly this was attained under strict cost and schedule constraints and through active engagement between various NASA divisions, academia, industry and other government agencies. TDMs were led by a clear roadmap of NASA’s mission areas to help identify crucial technologies that need to be developed for future missions [118, 119, 120].

Ten of the sixteen FBC missions were successful, and although this 63% success rate was considered by NASA to be too low, the FBC initiative still made significant achievements in facilitating technological innovation [117,121,122]. First, NASA is considered to have regained its capacity to make rapid progress to enable faster and cheaper technology demonstration through managerial reform [115, 116, 117,122, 123, 124, 125]. Second, and as Ward (2010) suggested, in highly regulated industries where products are considered prohibitively expensive “the important thing is not how much success we get out of 100 tries, but rather, how much success we get out of 100 dollars”, and all sixteen FBC missions were commissioned at a cost cheaper than a traditional NASA mission such as the Cassini mission to Saturn which cost $3.9 billion [121, 122] .The initiative also demonstrated that safety and performance need not be compromised to achieve FBC technology demonstration [117, 124, 125, 126].

Programmes initiated during the FBC era exist to this day and more have been added under the same premise; however, some argue that following Goldin’s departure in 2002 the FBC philosophy was not upheld [ 123], which allowed the legacy of cost and schedule overruns at NASA to return and continue and this further illustrates the critical role of management in enforcing positive organisational change.

The Commercial Orbital Transportation Services Program, SpaceX and an Enabling Context

After the fall of the Soviet Union the American Government encouraged collaborating with Russian engineering firms to prevent the trade of Russian rockets to U.S. adversaries [110, 111]. As a result, R&D in rocket engines stalled and until recently there was a heavy reliance on the technically superior Russian technology for both civilian and military missions [110, 111, 127]. The COTSP was introduced in 2006 to decrease the reliance on foreign capabilities for cargo transportation by building domestic capabilities to maintain U.S. leadership in space [108]. Building such capabilities was also thought to support the growth of the national economy [106]. Therefore, the decision was made to transfer low-Earth orbit operations and cargo transportation to the private sector to free NASA to focus on high-risk, long-term R&D [116].

In its analysis of the COTSP, the Breakthrough Institute focused on the roles NASA and the U.S. Government have played in encouraging the engagement and success of private companies within commercial spaceflight [24, 25]. This research has expanded on that to explore the interplay between the technically astute NASA and the innovative organisational culture within SpaceX that, together, resulted in the success of the programme.

NASA realised that for the successful commercialisation of space transportation, a commercial friendly framework was needed to incentivise the engagement of the private sector. NASA’s approach to lowering barriers to entry was based on other successful ventures where “government strategic planning and investment led to the success of (…) new industries” [106]. Therefore, a ‘cost effective capability’ was sought where the national strategic benefits would outweigh the costs of enabling a domestic capability [106].

The funding for the COTSP was highly restricted in comparison to other programmes at NASA because it was perceived as a risky endeavour liable to fail [106, 128]. NASA therefore realised that reducing overhead costs would mitigate some of this risk by dedicating more funds towards the development of technical capabilities [106]. NASA also demanded match funding from its commercial partners (SpaceX) and liability for any ensuing cost overruns (see Figure 9). Guaranteed funding and a guaranteed number of missions to the International Space Station (ISS) for the duration of COTSP were offered to the private partner, and technical milestones were set up. NASA’s funds were released subject to SpaceX achieving those milestones. SpaceX had “to raise the money to make it from one milestone to the next. If they succeeded, NASA would make payment and keep them going.”[106]. To NASA setting up such a framework, rather than setting up a traditional cost-plus procurement contract, meant their private partner would ‘have skin in the game’ and would be incentivised to ensure the success of the venture [106].

Figure 9. Total Investment in COTSP (NASA, 2014)

There was close coordination between NASA centres and SpaceX, which was facilitated by the COTSP Advisory Team (CAT). A fundamental criterion to be met by CAT members was the adoption of a results-oriented rather than process-focused approach. CAT members who did not embrace this mind-set were removed from the programme despite the scarcity of experts available within NASA, because that stance was perceived to be vital in ‘protecting’ the culture at SpaceX whilst providing necessary technical guidance [130]. The basic principles of the COTSP are illustrated in Figure 10.

Figure 10. Basic Principles of the Commercial Orbital Transportation Services Program

A vital element in the success of SpaceX was the guidance the CAT members provided, especially the close interaction with NASA’s Safety Officers, which allowed the introduction of practices new to NASA and accelerated technological development and demonstration [106, 128, 129]. The CAT members were also critical in keeping NASA’s bureaucracy at bay and granting SpaceX the freedom to develop and fail within a ‘safe environment’ to allow learning-by-doing [19, 106, 128].

SpaceX – Capitalising on Ancillary Technologies

SpaceX from inception has been driven by the vision to “revolutionize space technology, with the ultimate goal of enabling people to live on other planets” [130]. When Elon Musk, founder of SpaceX, recognised in 2002 that achieving that vision was to be prohibitively expensive with existing capabilities, he worked from first principles to suggest that rockets could be made and payload could be launched at much cheaper rates than what the market was offering [131]. Since the space industry is heavily regulated SpaceX realised that it would be best to work with existing technologies but target cost savings in their manufacturing and integration [19] i.e. adopt a proven rocket engine but standardise its design and assembly and introduce cheaper ways of integrating the engine’s components. Hence, driving down cost through the increased adoption of effective ancillary technologies rather than developing a novel technology, was the innovation sought at SpaceX [19].

Equipped with driven integrated teams, a flat organisational structure and a culture likened to Lockheed Martin’s Skunk Works [128], SpaceX challenged the status quo and adopted a lean and efficient approach to rocket delivery focused on cost reduction, modularisation and standardisation [128,129, 132] suggested that to enable such a business model and culture, SpaceX focused on setting up in-house manufacturing facilities to enable a non-traditional cost model, which granted SpaceX more control over spending and design. As an example, changes in preliminary designs, which are anticipated in any technology development programme, under traditional procurement routes would require renegotiating supplier contracts and incur extra costs and time. Retaining an in-house facility eliminated the need for external suppliers, which lead to cost- and time-savings in the development programme, i.e. it enabled SpaceX to rapidly build and test affordable prototypes [132].

When it joined COTSP SpaceX was already an established company, but the disparity in experience and capabilities between themselves and NASA was considerable. The SpaceX solution to that was to capitalise on its in-house facilities to foster an accelerated Design-Build-Test programme, where each successful prototype was tested at least three times to ensure all the necessary learning and knowledge is developed and transferred within the team [132].

With its ability to rapidly produce affordable and testable systems SpaceX was able to adopt a ’spiral development’ approach to design and product development [128]. This approach was previously proposed within NASA around 2005 by its Associate Administrator for the Office of Exploration System [128]. The organisational and cultural ‘norms’ within NASA however turned down the spiral development approach in favour of design optimization [128, 132]. This spiral development model originated in software engineering and is a “risk-driven process” that guides the integration of complex engineering systems [133]. as illustrated in Figure 11, this model proposes “a cyclic approach for incrementally growing a system’s degree of definition while decreasing its degree of risk”, and offers a set of milestones to ensure the feasibility and adequacy of the developed engineering solution(s) [133].

Figure 11. The Spiral Development Model (Boehm and Hansen, 2000, p.2)

SpaceX therefore came to NASA and COTSP with a lean management model that capitalised on in-house capabilities and facilities to allow rapid prototyping and integrated learning and knowledge transfer. The SpaceX organisational model is illustrated in Figure 12.

Figure 12. SpaceX: A Distinct Organisational Model in the U.S. Space Industry

It was highlighted previously that SpaceX was focused on lowering the costs of rocket production and launch; therefore, following a series of successful rocket launches the next step was to produce affordable reusable rockets [19]. The reason being that a large proportion of the cost associated with cargo transportation missions was the need to build a rocket from scratch for each mission[19]. The concept of reusable rockets was not devised by SpaceX [134], but was made commercially viable by their ability to reduce the time and resources allocated to refurbishment and checks in-between launches [23].

Technological innovation at SpaceX featured the introduction of standardised and commercial-off-the-shelf components (for e.g. microprocessors and pneumatic systems) that perform the same functions as expensive, legacy components [132, 135, 136, 137]. The combination of the spiral development approach, the in-house capabilities and extensive integration of software into the processes of SpaceX has allowed engineers to simulate and test their hardware and software rapidly and at affordable costs. For example, the spiral development approach allowed SpaceX to condense the time traditionally required for the verification and validation of spaceflight components, such as the pogo accumulator [132]. Pogo oscillation in spaceflight is a vibration response caused by rocket propulsion which “can result in the impairment of the astronaut crew, an unplanned engine shutdown, loss of mission, or structural failure” [138], and accumulators are used to suppress this phenomenon [138, 139]. A simulator was developed to ensure that accumulators are designed to adequately suppress the pogo effect, and this simulator is adopted by “all U.S. rocket makers” [132]. It would usually take several months to run the simulations and then design and build the accumulators [132]. With its rapid prototyping and intense design-build-test approach, SpaceX was able to prototype and test their built accumulator within three days [132]. It was also found that custom-built harnesses used to strap in astronauts cost nearly $50,000 per harness for a number of reasons including the fact that they are considered space-qualified components [135]. SpaceX decided to adopt the safety belts used in racing cars, which were more comfortable and cost only $2,000 per belt and demonstrated to NASA their safety and reliability [135].

SpaceX therefore fostered management and engineering practices considered different from the overarching principles and incumbent practices within the conservative U.S. space [128, 129, 132, 140], and this falls under the premise of organisational innovation. In 2015 SpaceX managed to land its booster rocket intact after a payload mission to the ISS [23, 141]. To prove the commercial success of their distinct management and engineering approach the launch costs SpaceX offer are nearly a third of those projected by NASA and United Launch Alliance (ULA) costs, who since 2007 has had the major share in civilian and military launch missions [141,142]. Until SpaceX established itself as the only competitor, there was a lack of incentive in incumbents in the military launch sector to seek cost savings due to the cost-plus nature of their contracts [142, 143].

Today SpaceX as a private entity is able to achieve what many perceived unattainable in the near future [141]; it provides a competitive American launch capability that dominates the global commercial launch market as shown in Figure 13. SpaceX delivered a cost-effective space transportation capability not through a new rocket-launch technology, but through organisational practices that accelerated the demonstration and adoption of ancillary technologies resisted by the conservative space community [144]. In launching its Falcon Heavy Rocket, SpaceX also produced a rocket capable of lifting 64 tonnes of cargo at a maximum of $150 million [20]. By comparison, ULA currently offers the same capability for a contested $350 million, while NASA continues to develop its Space Launch System with a 70-tonne capacity at an estimated $2 billion budget per annum since 2011 [20, 145].

Figure 13. Awarded Global Commercial Launch by Market Share (U.S. Congress, 2017)

Lessons in Change Management from the Comparative Study

This comparative study presents a number of significant lessons in the U.S. space sector that can be taken on by the UK nuclear sector. These lessons are distilled and illustrated in Figure 14 as the recognition of a strategic problem by the U.S. Government, its intervention through NASA and finally facilitating the innovative solutions offered by SpaceX as a commercial player.(Figure14)

Figure 14. Lessons Learned from the U.S. Space Industry

Definition of a Strategic Problem

The reliance of U.S. Government on foreign capabilities, especially for the delivery of sensitive military cargo, raised security concerns within policy-makers and presented a national strategic challenge. Despite the significant public funds directed towards NASA and private bodies such as ULA, the costs of cargo launch were still high and prohibitive. NASA was therefore charged with devising a policy intervention that would deliver a cost-effective American capability through the private sector. NASA with is expertise realised that to achieve that goal a commercial friendly framework was required to attract an innovative and agile private partner, and incentivise their engagement and investment [106].

U.S. Government’s Intervention: NASA’s COTSP

COTSP to NASA represents a change from traditional procurement routes and interactions with the private sector, a change that was deemed necessary to achieve a national directive. COTSP is therefore an example of a successful government intervention, which reveals how an effective collaborative framework between government and industry can resurrect domestic capability through the private sector. The success of COTSP also signalled a shift in the role of the private sector in the commercial space transportation industry. Instead of procuring cheaper discrete components or services through the private sector, NASA enabled a system provider to emerge (see Figure 15). NASA’s collaborative framework facilitated the technological and organisational innovation offered by SpaceX and delivered a holistic technical solution to a strategic challenge.

Figure 15. Manufacturing Tiers in Space Supply Chain (Bryce, 2017)

Facilitating Innovative Solutions Offered by Private Sector

The limited success of the FBC initiative versus the prominence of SpaceX reveals the close relationship between organisational culture, business practices and the effectiveness of technological innovation, i.e. the critical role of organisational change as a catalyst. SpaceX, with its achievements and competitive in-house launch capabilities, has reignited interest in space exploration for observers and professionals alike. As a result, SpaceX is currently a valuable ‘national asset’ to NASA, the Department of Defence and the national American economy.

This comparative analysis of the space sector highlights the negative impact of stagnation or decline in technological innovation, especially in an industry of national strategic importance. These negative consequences in the U.S. space industry were primarily the escalating costs of space missions and waning domestic capabilities, which led to an increased reliance on foreign capabilities. Through institutional and organisational change, which enabled accelerated technology demonstration and adoption, the costs of deployed missions were greatly reduced without compromising the safety and integrity of installed systems. Therefore, if the UK nuclear industry is to focus on technological innovation without first establishing an enabling context that successfully integrates organisational innovation, this may lead to a repeat of the FBC initiative which experienced a limited, unsustainable technological success.

Establishing this enabling context in the UK nuclear industry involves tackling the demand for nuclear-new-build. However, there are differences in the market dynamics between the U.S. space and UK nuclear industries. In the 1980s, there were movements to reduce government spending on the space industry in the U.S. and the nuclear industry in the UK [18, 41, 114]. The move towards commercialising the industries’ activities was thought, by governments, to decrease public spending and “save government money in the long run” [18, 41, 146]. In both industries there was, therefore, a reliance on market forces to drive commercial activities [41, 109, 147]. However, in the space industry market forces proved to be insufficient to drive change and tackle the high costs of low-Earth orbit operations due to uncertainty in long-term demand [148]; analogous with the nuclear-new-build market in the UK.

As discussed, and with regard to the UK nuclear sector, following the privatisation of electricity generation and distribution in 1990, the ownership of nuclear-new-build initiatives was completely shifted to the private sector in 1996, but by 2005 there was no domestic reactor vendor capable of delivering nuclear new build projects in the UK or abroad [41]. With regard to the U.S. space industry, the number of private companies involved in delivering launch vehicles shrunk from 20 to three major companies in 1997 [148]. It was recognised that growth in both markets (nuclear-new-build and low-Earth orbit launch) was dependent on economic and political factors [40, 64, 109].

In the case of the U.S. space industry, the US government is a major customer for launch activities. NASA recognised that a “steady supply of cargo” to the International Space Station was a viable market [146]. By facilitating entry to that market, and by shifting NASA’s role from a supervisor of private contractors to a customer and partner, the COTSP succeeded in leveraging private funding and creating a “broader more competitive industry”, despite “tight budgets and political contention” and high commercial risk at the time [146, 149].

In comparison, the customer for nuclear-new-build initiatives in the UK is the private sector and, based on the withdrawal of Toshiba and Hitachi-GE, the deployment opportunities available within the UK market did not counteract the high commercial risk these private developers were exposed to. On the other hand, the market for decommissioning activities, based on contracts issued by the Nuclear Decommissioning Authority (an executive non-departmental public body), has been evolving due to foreseen demands which led to an increased investment and engagement from the private sector in R&D activities [67].

The U.S. space case study has, therefore, shown that in highly regulated industries where technological innovation faces various adoption challenges (despite their potential to address fundamental issues such as prohibitive costs and build schedules), the underlying issues are more likely to be institutional and organisational than technical. This research has revealed similar underlying issues in the UK nuclear industry. In parallel, the report issued by the Breakthrough Institute gained political traction and a further study was commissioned to recommend improvements to U.S. policies and regulation to reduce barriers to entry, with a focus on ‘micronuclear reactors’ and advanced nuclear technologies [150]. The U.S. senate has also passed the Nuclear Energy Innovation Capabilities Act and introduced the Nuclear Energy Leadership Act with the purpose of regaining U.S. leadership in nuclear technology and encouraging the delivery of cost-effective, advanced nuclear technology through American capabilities – a directive similar to that of COTSP [151, 152]. And more recently the Nuclear Innovation Alliance in the U.S. issued a report “in search of a SpaceX for nuclear energy … to return the United States to a leadership role” and dominate the export market [153].

Therefore, changes would be needed in the UK nuclear industry to achieve a collaboration model to similar to COTSP. The UK Government has to “decide whether it wishes the UK [to capitalise on existing domestic capabilities] to be a serious player in developing nuclear generation technology as a designer, manufacturer and operator or alternatively to restrict its interest to being an operator of equipment supplied by others from overseas. (…) [B]eing a technology manufacturer would require a step change in the level of Government funding and a long-term commitment by the Government to providing underpinning strategic support.” [95].

This research has shown, through a closer look at the nuclear and space industries, the negative effects of constrained innovation management on an industry of national strategic importance. Some of these effects include a slow response to urgent policy or landscape changes, a waning of domestic capabilities, rising costs of deployment and longer delivery time. The U.S. Government eventually reacted to these very issues to demand and enable reform within the space industry by collectively addressing the policy, regulatory and commercial context of the industry.

The U.S. space case study has shown that a viable collaborative framework between government and industry supported by national policy, is capable of encouraging organisational innovation within highly-regulated industries, to then facilitate technological innovation and drive down costs and delivery time through effective innovation practices. The success of COTSP, a government intervention within a highly-regulated industry like space, has significant implications on the findings of this research and enabling organisational innovation and the adoption of effective ancillary technologies in nuclear-new-build projects in the UK.

First is the recognition of the strategic value in nurturing a domestic capability, at a high political level. This domestic capability could be nurtured by government enabling ‘technology vendors’ to emerge through a guaranteed set of deployment opportunities, and an effective collaborative framework between government and industry. The national strategic imperative behind COTSP meant NASA had to revisit and reassess its organisational practices to support developing American capabilities within the private sector and delivering affordable spacecrafts. NASA’s self-examination led to an institutional change which culminated in a commercial friendly framework despite budgetary and resource constraints. In highly regulated industries, this framework should include the regulator as was observed in the close interaction between SpaceX engineers and NASA’s Safety Officers, to help reduce the commercial risk, cost and time associated with technology demonstration. For the nuclear sector, this would not be an unprecedented step: this was the premise behind the ONR introducing the Generic Design Assessment approach [147]. The UK Government is therefore encouraged to devise and oversee an enhanced industry-regulatory engagement framework where the regulator becomes an innovation catalyst not far removed from the innovation process within the industry, while retaining the value it has from its complete independence.

Second, the collaborative framework set up by the COTSP supports the research recommendations provided in Section 5.4; COTSP offered guaranteed deployment opportunities and public funds, albeit limited in comparison to NASA’s overall budget, which created an operating environment that incentivised engagement and investments from the U.S. private sector. However, it was organisational innovation, incentivised by this enabling context and market demand, that underpinned the commercial and technological success of SpaceX.

Introducing a collaborative framework within the UK nuclear industry would be an effective first step to enabling innovation. The next steps include creating deployment opportunities and financial incentives for the private sector to facilitate technological and organisational innovation in nuclear-new-build projects. Through the adoption of effective ancillary technologies, facilitated by organisational innovation and accelerated technology demonstration, the UK private sector can address the affordability and delivery challenges facing nuclear-new-build to support the deployment of domestic technologies. Intensified public engagement and government support could also help raise public interest in the nuclear industry as a technology that could facilitate a rapid transition to low carbon power in the global efforts to tackle climate change.

The findings of the research are summarised in Figure 16. Additional areas to support these findings involve creating a roadmap to facilitate organisational change within the UK nuclear private sector. It is anticipated that a viable organisational innovation model would reduce perception barriers and drive down the costs and risks associated with technology demonstration programmes to achieve effective technological innovation. Close interaction with professionals in the nuclear industry will be used to determine:

- the transferrable lessons learned from the space comparative study; and

- possible organisational change strategy for these lessons to be successfully translated. (Figure 16)

Figure 16. Proposed Institutional and Organisational Change to Facilitate the Adoption of Ancillary Technologies in Nuclear-New-Build in the UK

- Danby G (1996) Nuclear Privatisation. In: House Of Commons Library Research Paper 96/3 (ed.). [crossref]

- IEA/NEA (2015) Technology Roadmap. Nuclear Energy. Nuclear Energy Agency, International Energy Agency. [crossref]

- Johnstone P and Stirling A (2015) Comparing Nuclear Power Trajectories in Germany And the UK: From ‘Regimes’ to ‘Democracies’ in Sociotechnical Transitions and Discontinuities. SSRN. [crossref]

- Kessides IN (2010) Nuclear power: Understanding the economic risks and uncertainties. Energy Policy 38: 3849-3864. [crossref]

- NEA (2015) Nuclear New Build: Insights into Financing and Project Management. Nuclear Development. Paris: Nuclear Energy Agency.[crossref]

- Trancik JE (2006) Scale and innovation in the energy sector: a focus on photovoltaics and nuclear fission. Environ Res Letts. 1. [crossref]

- Węglowski MS, Błacha S, Phillips A (2016) Electron beam welding – Techniques and trends. Review. Vacuum 130: 72-92. [crossref]

- EPRI (2015b) Reduced Pressure Electron Beam Welding of Thick Section Vessel Steels. [crossref]

- Barker B (2017) EPRI Investigates Automated, Real-Time Monitoring with Wireless Sensors. EPRI J 6. [crossref]

- Fuhr P( 2016) Wireless sensor networks for the monitoring and control of nuclear power plants. [crossref]

- Laikari A, Flak J, Koskinen A, et al. (2018) Wireless in Nuclear: Feasibility Study. Nordic Nuclear Power Plants. Energiforsk. [crossref]

- Hashemian HM (2011) What You Need to Know about Sensor Reliability Before and after an accident. In: IAEA, ed. IAEA TWG NPPIC Meeting. [crossref]

- Punshon CS ( 2004) Reduced Pressure Electron Beam Welding in the Power Generation Industry. Sixth International EPRI Conference. Sandestin Golf and Beach Resort, Sandestin, Florida: The Welding Institute. [crossref]

- Cowan R (1990) Nuclear Power Reactors: A Study in Technological Lock-in. JEH 50: 541-567.

- Goldberg SM, Rosner R (2011) Nuclear Reactors: Generation to Generation. [crossref]

- Greenhalgh C, Azapagic A (2009) Review of drivers and barriers for nuclear power in the UK. Environmental Science and Policy 12: 1052-1067. [crossref]

- Kagramanyan V (2012) Nuclear Energy: Prospects and Market Effects. Global Nuclear Markets: Changes in the Strategic Landscape. Abu Dhabi, U.A.E.: The Emirates Center for Strategic Studies and Research.

- Pearson P, Watson J (2012) UK Energy Policy 1980-2010: A history and lessons to be learnt. London: Institute for Engineering and Technology. [crossref]

- Agan T (2013) What SpaceX Can Teach Us About Cost Innovation. Harvard Business Review. [crossref]

- Berger E ( 2018) The Falcon Heavy is an absurdly low-cost heavy lift rocket [Online]. Ars Technica. [crossref]

- Bryce ( 2017) New Kids on the Block: How New Start-Up Space Companies Have In uenced the U.S. Supply Chain. [crossref]

- NASA (2014) Commercial Orbital Transportation Services: A New Era in Space ight. [crossref]

- Selding PBD (2016) SpaceX’s reusable Falcon 9: What are the real cost savings for customers? [Online]. SpaceNews. [crossref]

- Lovering J, Nordhaus T, King L (2017) How to Make Nuclear Innovative: Lessons from Other Advanced Industries. [crossref]

- Nordhaus T, Lovering J, King L (2017) Commercial Spaceflight: Case Study No. 1. How to Make Nuclear Innovative. [crossref]

- Antons D, Piller FT ( 2014) Opening the Black Box of “Not Invented Here”: Attitudes, Decision Biases, and Behavioral Consequences. Academy of Management Perspectives 29: 193-217. [crossref]

- Anzola-Román, P, Bayona-Sáez C, García-Marco T (2018) Organizational innovation, internal R and D and externally sourced innovation practices: Effects on technological innovation outcomes. J Business Res 91: 233-247. [crossref]

- Makó C, Mitchell B, Illéssy M (2015) Developing Dynamic Innovative Capabilities: The Growing Role of Innovation and Learning in the Development of Organisations and Skills in Developed and Emerging Nations of Europe. JEIEE 1: 18 - 38. [crossref]

- OECD (2005) Oslo Manual, Statistical Office of the European Communities. [crossref]

- Tushman ML, Smith WK (2002) Organizational Technology. In: BAUM, J. (ed.) The Blackwell Companion to Organizations. Blackwell Publishers Ltd. [crossref]

- WNA (2018) Economics of Nuclear Power. [crossref]

- BEIS (2018a )Advanced Modular Reactor (AMR) Feasibility and Development (F&D) Project: Abstracts from the Applicant Organisations' Proposals. Department for Business, Energy & Industrial Strategy. [crossref]

- NEI (2019) Canada SMR race expands to six entrants [Online]. Nuclear Energy Insider. [crossref]

- Canadian Nuclear Laboratories (2017) CNL releases summary report on Small Modular Reactor RFEOI (Request for expression of interest) [Online]. [crossref]

- WNN (2019) SMR proposals progress through Canadian process [Online]. World Nuclear News. [crossref]

- NUSCALE. 2019. NuScale Wins U.S. DOE Funding for its SMR Technology [Online]. NuScale Power LLC. [crossref]

- DECC (2016) Small Modular Reactors Competition: Phase One. In: CHANGE, T. D. O. E. A. C. (ed.). London. [crossref]

- House Of Commons (2006) Keeping the lights on: Nuclear, Renewables and Climate Change. London: Environmental Audit Committee. [crossref]

- NAO (2016) Nuclear Power in the UK. National Audit Office. [crossref]

- NAO (2017) Hinkley Point C. Department for Business, Energy & Industrial Strategy. [crossref]

- Taylor S (2016) The Fall and Rise of Nuclear Power in Britain: A History, Cambridge, UIT Cambridge Ltd. [crossref]

- Yin RK (2013) Case study research : design and methods, Los Angeles, California : SAGE. [crossref]

- Byrne D (2011) What is an Effect? Coming at Causality Backwards. In: Williams, M, Vogt, W. (eds.) The SAGE Handbook of Innovation in Social Research Methods. London. [crossref]

- Byrne D, Ragin C (2009) The SAGE Handbook of Case-Based Methods. London. [crossref]

- Gilbert Gn, Stoneman P (2016) Researching social life, Los Angeles, Sage. [crossref]

- Porta Dd ( 2008) Comparative analysis: case-oriented versus variable-oriented research. In: Della Porta D, Keating M (eds.) Approaches and Methodologies in the Social Sciences: A Pluralist Perspective. Cambridge: Cambridge University Press. [crossref]

- Stern E, Stame N, Mayne J, etal. ( 2012) DFID Working Paper 38. Broadening the range of designs and methods for impact evaluations. In: DEPARTMENT FOR INTERNATIONAL DEVELOPMENT (ed.). London. [crossref]

- Ragin C C, Becker Hs (1992) What is a case? : exploring the foundations of social inquiry, Cambridge, Cambridge Univeersity Press. [crossref]

- Ragin C C (1987) The Distinctiveness of Comparative Social Science. In: Ragin CC (ed.) The Comparative Method Moving Beyond Qualitative and Quantitative Strategies. University of California Press. [crossref]

- Byrne D (2011) What is an Effect? Coming at Causality Backwards. In: WILLIAMS, M. & VOGT, W. (eds.) The SAGE Handbook of Innovation in Social Research Methods. London. [crossref]

- Byrne D, Uprichard E (2012) Useful Complex Causality. Philosophy, Philosophy of Science, Metaphysics [Online]. [crossref]

- Byrne D (2005) Complexity, Configurations and Cases. Theory, Culture and Society. Sage J 22: 95-111.

- Bolton R, Foxon T (2013) Negotiating the energy policy ‘trilemma’ – an analysis of UK energy governance from a socio-technical systems perspective. [crossref]

- DTI (2007) Meeting the Energy Challenge A White Paper on Energy. In: INDUSTRY, D. O. T. A. (ed.). London: The Stationery Office Limited. [crossref]

- DECC (2011) The Carbon Plan: Delivering our low carbon future. In: Department of Energy & Climate Change (ed.). [crossref]

- DECC (2015a) Annex D: Major events in the energy industry. Department of Energy & Climate Change. [crossref]

- Cogent Skills (2010a )Next Generation: Skills for New Build Nuclear. In: THE NUCLEAR ENERGY SKILLS ALLIANCE (ed.) Renaissance Nuclear Skills Series: 2. Cogent Sector Skills Council.

- Cogent Skills (2010b) Power People: The Civil Nuclear Workforce. Renaissance Nuclear Skills Series. The Nuclear Energy Skills Alliance. [crossref]

- Interviewee #401 (2016) Interview Transcript #401. In: ABDALLA, A. (ed.) Technology Adoption EngD.,

- Vaughan A (2017) Nuclear plans 'should be rethought after fall in offshore windfarm costs'. The Guardian. [crossref]

- FT View ( 2016) China flexes its muscles over Hinkley Point [Online]. Financial Times. [crossref]

- Ward A, Pickard J, Stothard M (2016) Hinkley go-ahead after ‘national security’ safeguards. The Financial Times. [crossref]

- Jack S (2019) Why is the government cooling on nuclear? BBC. [crossref]

- Greg Clark Mp (2019) Statement on suspension of work on the Wylfa Newydd nuclear project. In: DEPARTMENT FOR BUSINESS, E. A. I. S. (ed.). [crossref]

- Hitachi (2019) Hitachi Announces Suspension of UK Nuclear Power Stations Construction Project and Posting of Impairment Loss and Related Expenses on Consolidated Basis, Posting of Extraordinary Loss on Unconsolidated Basis, and Revisions to Full-year Consolidated Business Forecast [Online]. [crossref]

- WNN (2018) Toshiba decides to scrap Moorside project [Online]. [crossref]

- NIRAB (2017b) The UK Civil Nuclear R and D Landscape Survey - February 2017. Nuclear Innovation and Research Advisory Board. [crossref]

- BEIS (2013) A Review of the Civil Nuclear R and D Landscape in the UK. Department for Business, Innovation and Skills. [crossref]

- NIRAB (2015) NIRAB Annual Report 2014. NIRAB-35-4 ed.: Nuclear Innovation and Research Advisory Board. [crossref]

- NIRAB (2017a) NIRAB Final Report: 2014-16. NIRAB-117-3 ed.: Nuclear Innovation and Research Advisory Board. [crossref]

- DECC (2015b) Sustaining our Nuclear Skills. In: CHANGE, D. O. E. C. (ed.). London. [crossref]

- Interviewee #105 (2016) Interview Transcript #105. In: ABDALLA, A. (ed.) Technology Adoption EngD.

- Ward A (2017) Nuclear industry warns of looming skills crisis. The Financial Times. [crossref]

- Interviewee #910 (2016) Interview Transcript #910. In: ABDALLA, A. (ed.) Technology Adoption EngD.

- ETI (2016) Preparing for deployment of a UK small modular reactor by 2030. Energy Technologies Institute. [crossref]

- Interviewee #101 (2016 )Interview Transcript #101. In: ABDALLA, A. (ed.) Technology Adoption EngD.

- Interviewee #301 (2016) Interview Transcript #301. In: ABDALLA, A. (ed.) Technology Adoption EngD.

- Skea J (2014) The renaissance of energy innovation. Energy & Environmental Science 7: 21-24. [crossref]

- Interviewee #810 2016. Interview Transcript #810. In: ABDALLA, A. (ed.) Technology Adoption EngD.